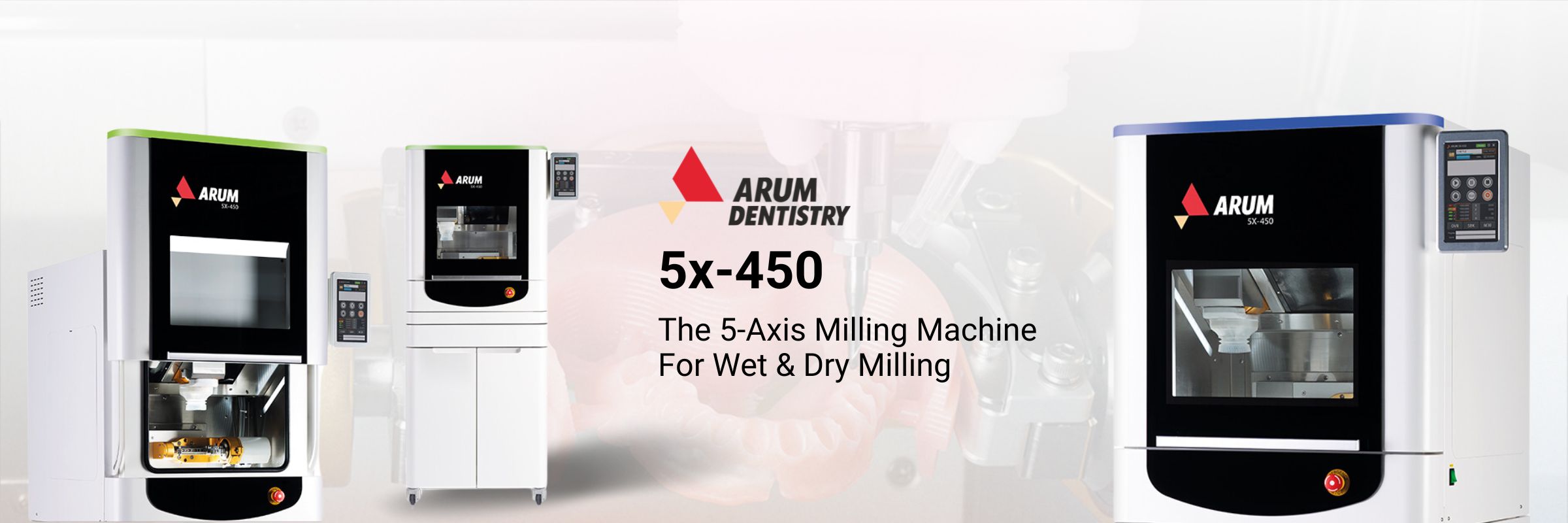

Arum 5x-450 Dental Milling Machine

Overview

The Arum 5x-450 is a cutting-edge dental milling unit designed to deliver precision, versatility, and efficiency in the creation of various prostheses. Equipped with the best-in-class spindle AC 1.28kw, this model is capable of machining a diverse range of shapes and materials, ensuring optimal results for every dental requirement.

Whether it’s the intricate details of the labial side, the undercut zone, or the cuff side, the Arum 5x-450 ensures unparalleled precision with its advanced cartridge systems.

Key Highlights

Experience Precision and Versatility at an Affordable Price:

The 5X-450 offers exceptional machining capabilities for various prostheses, making it a cost-effective choice. Utilizing an open C-type cartridge, this mill allows precise machining of the Labial Side (Buccal Side) and Under-Cut zones, essential for intricate prosthetic work.

Powerful Spindle for Diverse Materials:

Empowered by the best-in-class AC 1.28kw spindle, the 5X-450 effortlessly handles materials like Denture, Zirconia, CAD Block, and Titanium milled Bar, excluding Ni-Cr/Co-Cr Disk. This versatility ensures optimal results across a spectrum of shapes and materials.

Enhancing Efficiency in Customized Abutment Production:

The 5X-450 enables the machining of Customized Abutments with the removal of connectors, using an AT Holder and Attachment. This innovative feature enhances bonding with upper prostheses, minimizing post-stage work and significantly improving overall work efficiency.

Unparalleled Expertise in Screw-Type Prostheses:

Benefit from ARUM’s unique asset – a dedicated template for ARUM and Implant Connection. Leveraging extensive know-how gained from machining 5X-200 screw-type prostheses to 5X-450, achieve high-quality screw-type prostheses, including Bars, Screw-Retained crowns, and Bridge.

Simple Yet Comprehensive Milling Capabilities:

Easily produce high-quality Customized Abutments with the 5X-450’s differentiated round bar machining. Whether Cuff Side (Gingival area), Occlusal Side, Connectorless, or Retention Groove, this mill, equipped with an AT cartridge, simplifies complex milling processes.

Effortless Maintenance for Optimal Performance:

The 5X-450 ensures optimal machine conditions with its Auto Calibration Function. Users can maintain peak performance anytime, and the Auto Calibration function, based on the location of Pre-milled Blanks, guarantees the production of high-precision Customized Abutments.

Technical Specification

| Axis | 5-Axis | |

|---|---|---|

| Processing | Wet and Dry | |

| Spindle Power | AC 1.28kw | |

| Max. RPM | 60,000 | |

| A.T.C | 15 | |

| Tool Shank (mm) | Ø6 | |

| Motor | Stepping | |

| Drive Mechanism | Ball Screw | |

| Way System | Linear Guide | |

| Machine Size (W*D*H) | 791*791*790mm | |

| Total Size (W*D*H) | 791*791*1657mm | |

| Weight (Machine / Table) | 185kg / 65kg | |

| Travel | X,Y,Z axis | 245*116*130mm |

| A axis / B axis | 360˚/ ±35.1˚ | |

Watch the Video

FAQ's

The ARUM 5X-450 offers exceptional machining capabilities for various prostheses while maintaining affordability. Utilizing an open C-type cartridge, this milling unit allows precise machining of the Labial Side (Buccal Side) and Under-Cut zones, crucial for intricate prosthetic work.

Empowered by the best-in-class AC 1.28kw spindle, the 5X-450 effortlessly handles materials like Denture, Zirconia, CAD Block, and Titanium milled Bar (excluding Ni-Cr/Co-Cr Disk). This versatility ensures optimal results across a spectrum of shapes and materials, making it a powerful choice for diverse prosthetic applications.

The 5X-450 enables the machining of Customized Abutments with the removal of connectors, using an AT Holder and Attachment. This innovative feature enhances bonding with upper prostheses, minimizing post-stage work, and significantly improving overall work efficiency in Customized Abutment production.

Related Products

Associated Brands